SELECT YOUR VENGEANCE CLUTCH

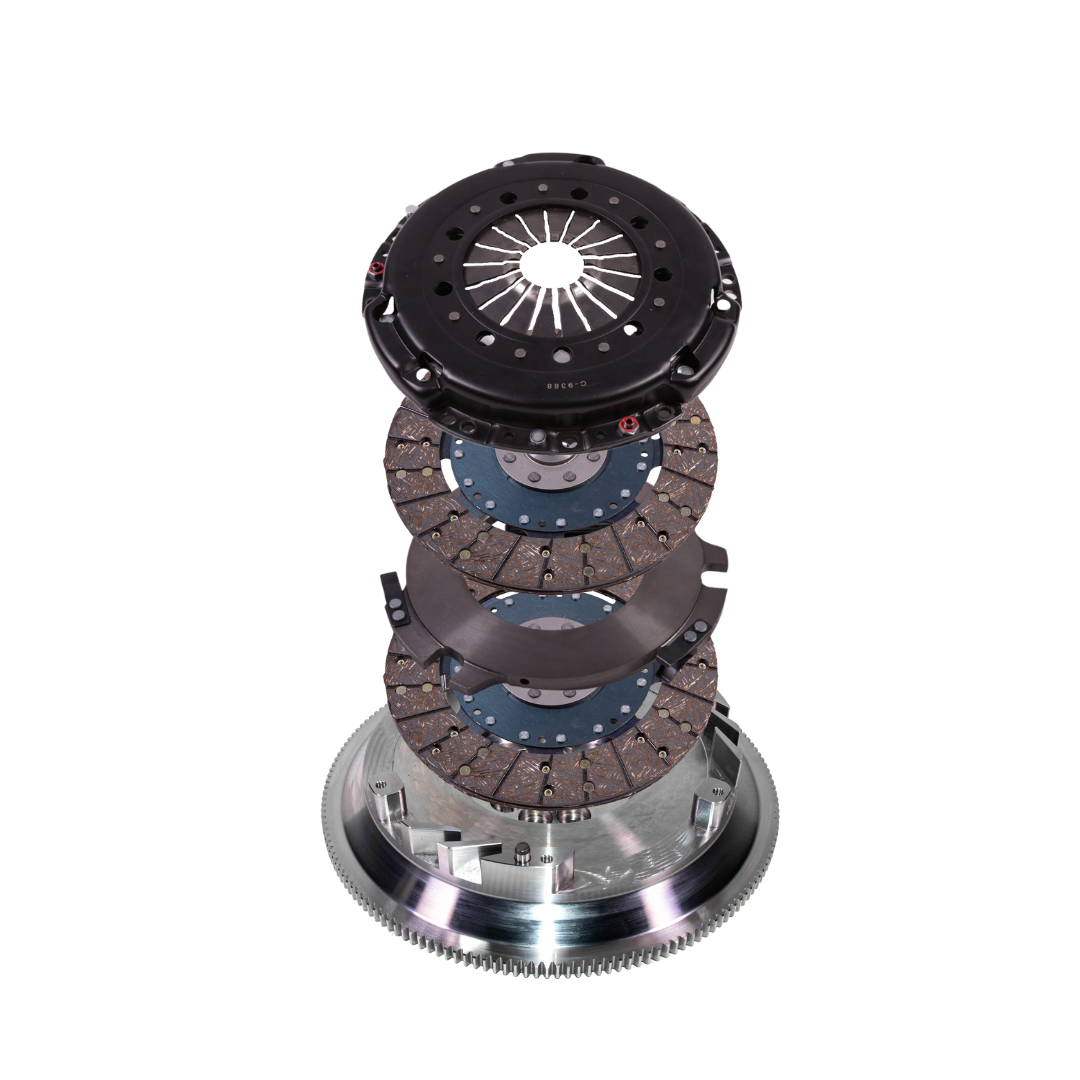

DM1 – (STAGE 1)

Featuring high-grade woven copper strands that increase strength and stabilize wear patterns throughout the unit’s service life, while stainless bonded backing plates enhance friction surface durability, preventing bursting and fragmentation. Rated for 450 to 650 wtq when installed and operated properly.

NOT RECOMMENDED FOR DRAG RACING

ALL MULTIPLATE CONVENTIONAL VENGEANCE CLUTCHES FEATURE:

Engineered for secure, vibration-resistant fastening, this locking nut features a set screw mechanism that prevents loosening under dynamic and high-torque conditions. Manufactured from high-strength alloy steel, it provides predictable performance in high-speed, high-load mechanical and automotive assemblies.

Designed for accurate engagement and controlled release, these set screws provide consistent torque and thread reliability. Constructed from heat-treated alloy or stainless steel, they ensure long-term durability, dimensional accuracy, and predictable disengagement under repeated cycling.

High-strength 12.9-grade socket head cap screws designed for maximum tensile and shear resistance, ensuring secure fastening of pressure plates in demanding clutch systems. Manufactured from heat-treated alloy steel, these bolts maintain integrity under extreme torque, vibration, and thermal cycling.

Precision flat washers distribute clamping load evenly, reduce surface wear, and prevent fastener loosening. Made from high-strength alloy steel, these washers enhance structural reliability in high-performance clutch assemblies.

Manufactured from heat-treated alloy steel or cast iron, this pressure plate delivers maximum clamping force and long-term fatigue resistance. Designed for high-performance and industrial applications, it maintains dimensional stability under repeated high-load and high-temperature cycles.

Constructed from heat-treated steel or alloy, the diaphragm fulcrum provides a stable pivot point for precise diaphragm actuation. Offers dimensional stability, fatigue resistance, and long service life in repeated high-load applications.

Engineered to provide high clamping force while minimizing bearing load, this diaphragm ensures smooth, predictable engagement. Manufactured from heat-treated spring steel, it maintains structural integrity and dimensional accuracy in performance and industrial clutches.

Solid Flywheel with a One Piece Ring Gear

Constructed from heat-treated alloy steel, the pressure ring provides consistent clamping force and uniform load distribution across friction surfaces, improving torque transfer and extending component life.

Engineered from high-grade alloy steel, these rivets maintain dimensional integrity and precise alignment under repeated high-load conditions. They provide exceptional tensile and shear strength, ensuring the pressure plate remains securely fastened.

Manufactured from high-strength alloy steel and precision hardened, this hub ensures robust torque transmission, long-term wear resistance, and fatigue durability under repeated cycles.

Constructed from heat-treated, high-strength materials, this midplate resists warping and deformation under high thermal and mechanical stress, ensuring consistent alignment and reliable torque transfer.

Precision-engineered clips made from heat-treated spring steel provide secure component retention, excellent fatigue resistance, and consistent engagement without permanent deformation under repeated cycling.

Advanced friction surfaces designed to deliver maximum grip, thermal stability, and wear resistance, ensuring consistent torque transfer and reducing the likelihood of glazing in high-stress operation.

Manufactured from high-strength, heat-treated alloy steel, these dowel pins provide accurate alignment of pressure plates with flywheels, maintaining concentricity under high-load conditions.

Constructed from 4140 Forged Steel Flywheel, this high-strength flywheel delivers superior balance, thermal stability, and long-term durability. Precision machining ensures minimal vibration, smooth rotational dynamics, and reliable torque transfer under high-speed, high-load conditions.

DM2 – (STAGE 2)

Utilizing segmented cerametallic friction discs that increase torque-holding capacity while maintaining smooth engagement across a variety of driving styles. Rated for 550 to 750 wtq when installed and operated properly.

NOT RECOMMENDED FOR DRAG RACING

ALL MULTIPLATE CONVENTIONAL VENGEANCE CLUTCHES FEATURE:

Engineered for secure, vibration-resistant fastening, this locking nut features a set screw mechanism that prevents loosening under dynamic and high-torque conditions. Manufactured from high-strength alloy steel, it provides predictable performance in high-speed, high-load mechanical and automotive assemblies.

Designed for accurate engagement and controlled release, these set screws provide consistent torque and thread reliability. Constructed from heat-treated alloy or stainless steel, they ensure long-term durability, dimensional accuracy, and predictable disengagement under repeated cycling.

High-strength 12.9-grade socket head cap screws designed for maximum tensile and shear resistance, ensuring secure fastening of pressure plates in demanding clutch systems. Manufactured from heat-treated alloy steel, these bolts maintain integrity under extreme torque, vibration, and thermal cycling.

Precision flat washers distribute clamping load evenly, reduce surface wear, and prevent fastener loosening. Made from high-strength alloy steel, these washers enhance structural reliability in high-performance clutch assemblies.

Manufactured from heat-treated alloy steel or cast iron, this pressure plate delivers maximum clamping force and long-term fatigue resistance. Designed for high-performance and industrial applications, it maintains dimensional stability under repeated high-load and high-temperature cycles.

Constructed from heat-treated steel or alloy, the diaphragm fulcrum provides a stable pivot point for precise diaphragm actuation. Offers dimensional stability, fatigue resistance, and long service life in repeated high-load applications.

Engineered to provide high clamping force while minimizing bearing load, this diaphragm ensures smooth, predictable engagement. Manufactured from heat-treated spring steel, it maintains structural integrity and dimensional accuracy in performance and industrial clutches.

Solid Flywheel with a One Piece Ring Gear

Constructed from heat-treated alloy steel, the pressure ring provides consistent clamping force and uniform load distribution across friction surfaces, improving torque transfer and extending component life.

Engineered from high-grade alloy steel, these rivets maintain dimensional integrity and precise alignment under repeated high-load conditions. They provide exceptional tensile and shear strength, ensuring the pressure plate remains securely fastened.

Manufactured from high-strength alloy steel and precision hardened, this hub ensures robust torque transmission, long-term wear resistance, and fatigue durability under repeated cycles.

Constructed from heat-treated, high-strength materials, this midplate resists warping and deformation under high thermal and mechanical stress, ensuring consistent alignment and reliable torque transfer.

Precision-engineered clips made from heat-treated spring steel provide secure component retention, excellent fatigue resistance, and consistent engagement without permanent deformation under repeated cycling.

Advanced friction surfaces designed to deliver maximum grip, thermal stability, and wear resistance, ensuring consistent torque transfer and reducing the likelihood of glazing in high-stress operation.

Manufactured from high-strength, heat-treated alloy steel, these dowel pins provide accurate alignment of pressure plates with flywheels, maintaining concentricity under high-load conditions.

Constructed from 4140 Forged Steel Flywheel, this high-strength flywheel delivers superior balance, thermal stability, and long-term durability. Precision machining ensures minimal vibration, smooth rotational dynamics, and reliable torque transfer under high-speed, high-load conditions.

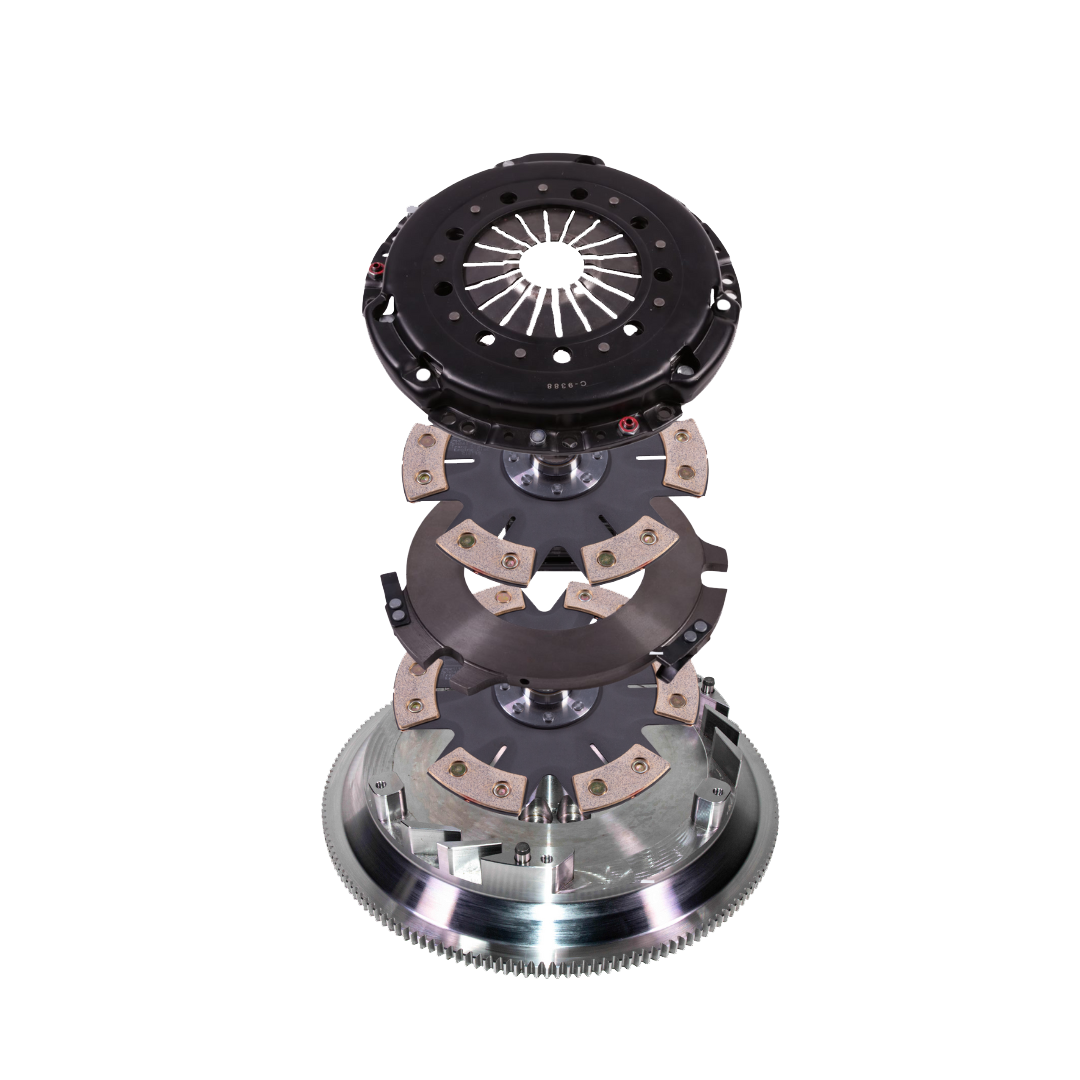

DM3 – (STAGE 3)

Featuring ceramic pucks that deliver reliable, instant response at the point of release. Its rigid design engages like a light switch. Ideal for spirited drivers and racers alike. Rated for 750 to 950 wtq when installed and operated properly.

ALL MULTIPLATE CONVENTIONAL VENGEANCE CLUTCHES FEATURE:

Engineered for secure, vibration-resistant fastening, this locking nut features a set screw mechanism that prevents loosening under dynamic and high-torque conditions. Manufactured from high-strength alloy steel, it provides predictable performance in high-speed, high-load mechanical and automotive assemblies.

Designed for accurate engagement and controlled release, these set screws provide consistent torque and thread reliability. Constructed from heat-treated alloy or stainless steel, they ensure long-term durability, dimensional accuracy, and predictable disengagement under repeated cycling.

High-strength 12.9-grade socket head cap screws designed for maximum tensile and shear resistance, ensuring secure fastening of pressure plates in demanding clutch systems. Manufactured from heat-treated alloy steel, these bolts maintain integrity under extreme torque, vibration, and thermal cycling.

Precision flat washers distribute clamping load evenly, reduce surface wear, and prevent fastener loosening. Made from high-strength alloy steel, these washers enhance structural reliability in high-performance clutch assemblies.

Manufactured from heat-treated alloy steel or cast iron, this pressure plate delivers maximum clamping force and long-term fatigue resistance. Designed for high-performance and industrial applications, it maintains dimensional stability under repeated high-load and high-temperature cycles.

Constructed from heat-treated steel or alloy, the diaphragm fulcrum provides a stable pivot point for precise diaphragm actuation. Offers dimensional stability, fatigue resistance, and long service life in repeated high-load applications.

Engineered to provide high clamping force while minimizing bearing load, this diaphragm ensures smooth, predictable engagement. Manufactured from heat-treated spring steel, it maintains structural integrity and dimensional accuracy in performance and industrial clutches.

Solid Flywheel with a One Piece Ring Gear

Constructed from heat-treated alloy steel, the pressure ring provides consistent clamping force and uniform load distribution across friction surfaces, improving torque transfer and extending component life.

Engineered from high-grade alloy steel, these rivets maintain dimensional integrity and precise alignment under repeated high-load conditions. They provide exceptional tensile and shear strength, ensuring the pressure plate remains securely fastened.

Manufactured from high-strength alloy steel and precision hardened, this hub ensures robust torque transmission, long-term wear resistance, and fatigue durability under repeated cycles.

Constructed from heat-treated, high-strength materials, this midplate resists warping and deformation under high thermal and mechanical stress, ensuring consistent alignment and reliable torque transfer.

Precision-engineered clips made from heat-treated spring steel provide secure component retention, excellent fatigue resistance, and consistent engagement without permanent deformation under repeated cycling.

Advanced friction surfaces designed to deliver maximum grip, thermal stability, and wear resistance, ensuring consistent torque transfer and reducing the likelihood of glazing in high-stress operation.

Manufactured from high-strength, heat-treated alloy steel, these dowel pins provide accurate alignment of pressure plates with flywheels, maintaining concentricity under high-load conditions.

Constructed from 4140 Forged Steel Flywheel, this high-strength flywheel delivers superior balance, thermal stability, and long-term durability. Precision machining ensures minimal vibration, smooth rotational dynamics, and reliable torque transfer under high-speed, high-load conditions.