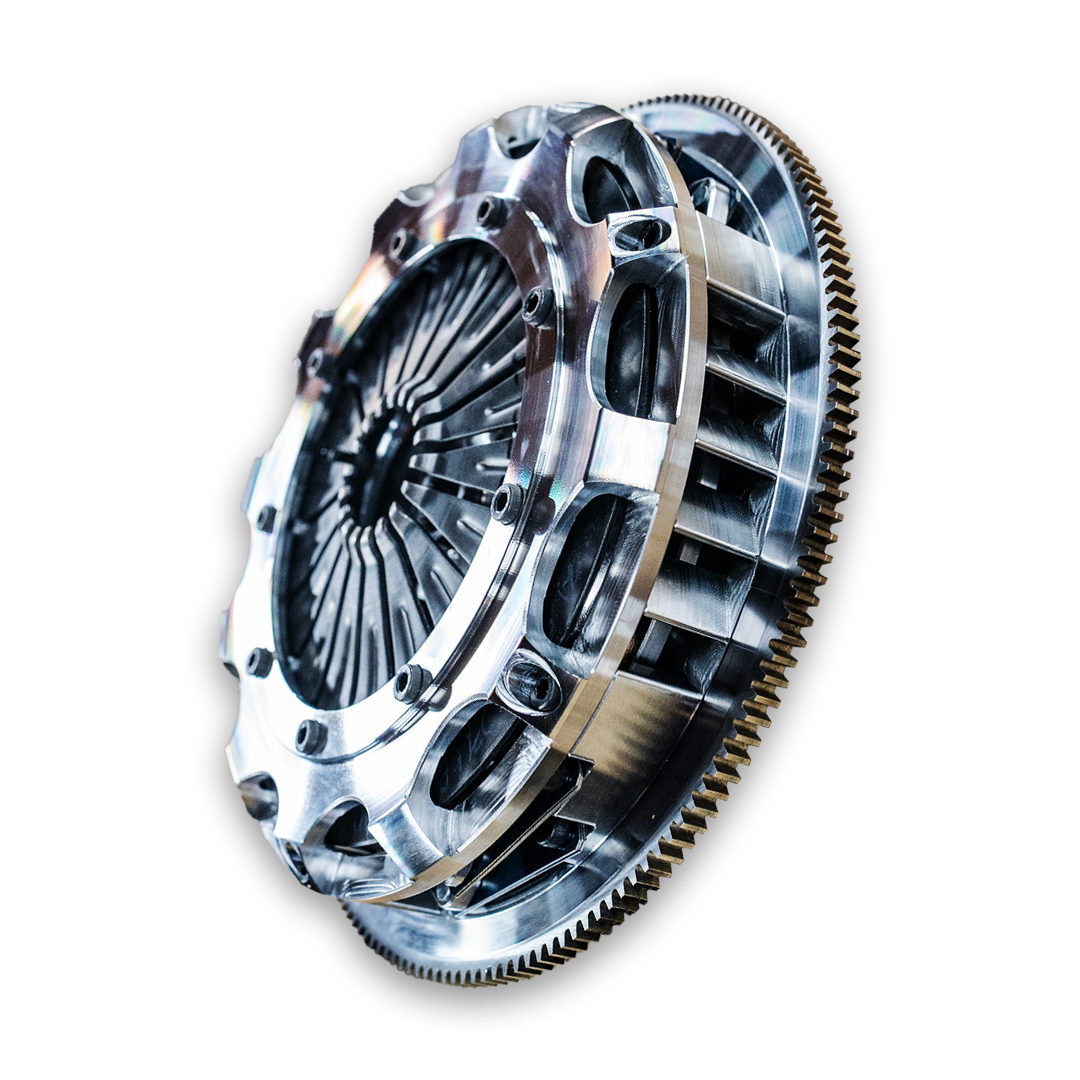

DM4 & DM5 (SPECIAL ORDER)

Our All-New FME 11-Inch Clutch Kit

BRING IT ON

Forged with American Steal

Machined balanced and assembled in USA

Tested guaranteed to provide uncompromised reliability

Street and Track for highly modified V8 application

ALL DM5 VENGEANCE CLUTCHES FEATURE:

High-strength 12.9-grade socket head cap screws designed for maximum tensile and shear resistance, ensuring secure fastening of pressure plates in demanding clutch systems. Manufactured from heat-treated alloy steel, these bolts maintain integrity under extreme torque, vibration, and thermal cycling.

Constructed from SAE4140 steel, this lightweight hat provides structural integrity, precise diaphragm engagement, and improved thermal dissipation. Reduced mass lowers rotational inertia, enhancing system responsiveness in high-performance clutch assemblies.

Manufactured from heat-treated spring steel, reinforced diaphragm maintains consistent clamping force and durability under repeated cycling, ensuring reliable performance in high-load and high-temperature applications.

Precision-engineered from SAE4140 steel, this retainer combines lightweight construction with robust structural support, maintaining precise diaphragm actuation under demanding conditions.

Engineered from high-strength steel alloy, this ring delivers high clamping force with reduced mass, improving system responsiveness and reducing fatigue on associated components.

High-strength alloy hub hardened for maximum wear resistance. Precision machining ensures accurate torque transfer and smooth engagement over repeated high-load cycles.

Advanced friction surfaces for predictable grip, reduced glazing, and thermal stability, ensuring consistent clutch performance under repeated high-stress conditions.

Constructed from high-strength SAE4140 steel, this midplate resists warping under elevated temperatures, maintaining structural integrity and dimensional accuracy./span>

Heat-treated, triple-layer straps engineered for even load distribution and resistance to buckling, ensuring reliable torque transfer during extreme load events.

Engineered to maximize airflow and heat dissipation, maintaining optimal operating temperatures and reducing component fatigue.

Precision-engineered channels direct airflow through the flywheel, preventing thermal buildup, warping, and maintaining dimensional stability.

Combined support structure provides enhanced load transfer, precise alignment, and reduced failure points, improving system durability.

CNC-machined from high-strength billet steel, this flywheel delivers superior structural integrity, minimal rotational inertia, and precise starter engagement for high-performance applications.

SELECT YOUR VENGEANCE CLUTCH

Or search: